As we noted in the last hot water project blog, the customer noted that the steam pressure varied and the steam control valve position did not necessarily represent the steam flow to the heater. Let’s get the steam under control.

We tell the customer that the addition of instrumentation to the steam lines will cost more than the previous instruments we have already added. They indicate that even small reductions in the loss of reactants would cover any of the costs of new instrumentation.

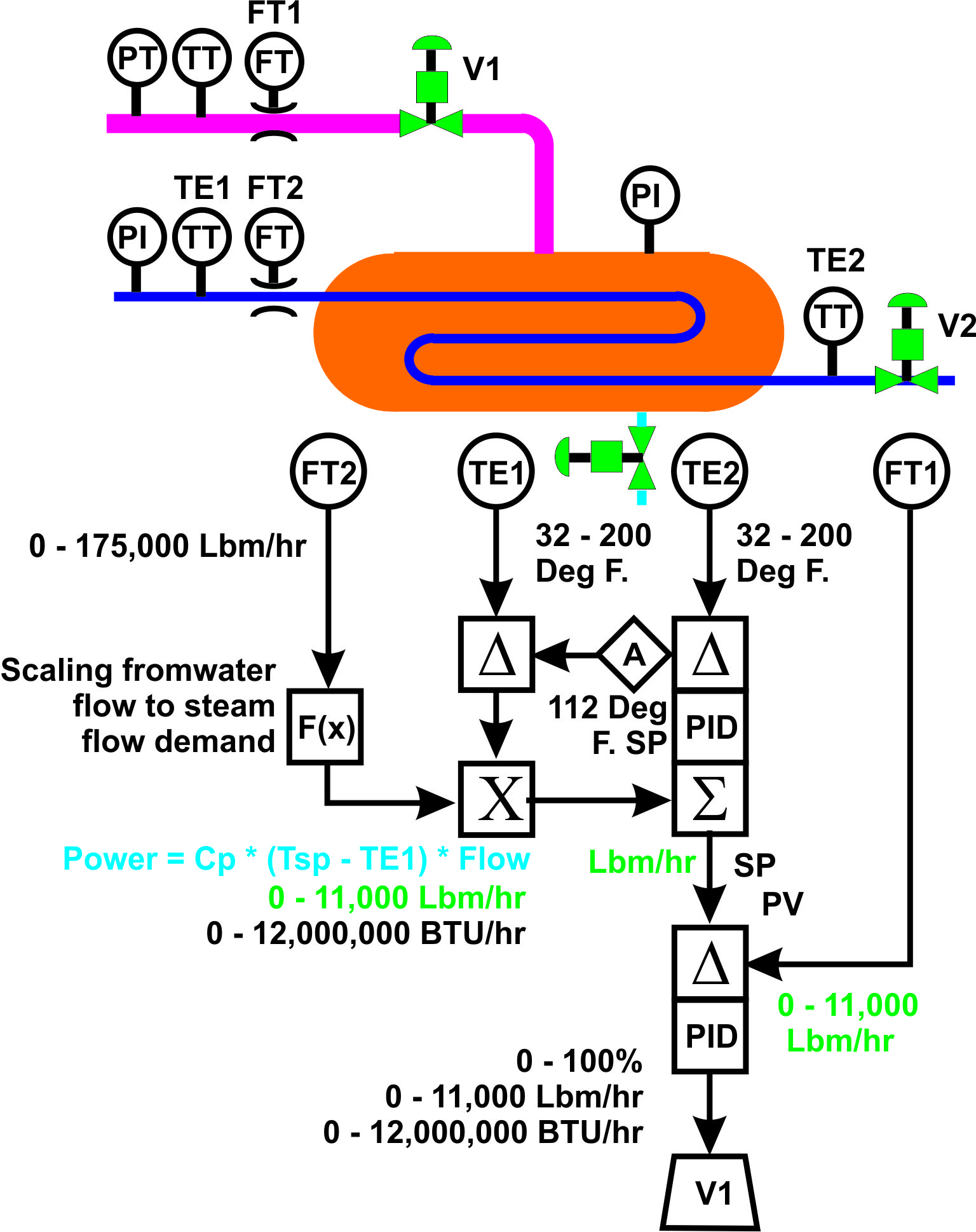

We inform the customer that we will add a temperature compensated steam flow meter and reconfigure the controls to accommodate the new instrumentation. The following is the new control arrangement.

You will note that we have now moved from a simple feed forward control to a feed forward – cascade control system. The reason for the cascade is we now are actually controlling the steam flow by manipulating the steam valve. The “inner loop” (steam flow) will be tuned first and then the “outer loop” (steam flow demand) will be tuned. The feed forward is now rescaled from valve position to steam flow demand. And again we implement and tune the new configuration. The customer is happy with the new and smaller error band of the water temperature.

The customer calls again in several months and indicates that they have related some small temperature differences in the water to incoming steam temperature. Reducing these temperatures could again reduce the loss of reagent in the bioreactors. We have one final change and inform the customer that it will not require the addition of any instrumentation – only some engineering and reconfiguration of the control arrangement. The following is what was proposed.

In this case we add an enthalpy calculation to the steam. Some manufacturers have this block built-in to their algorithm set but in most cases this calculation is performed using multiple blocks. Using the steam pressure and temperature we can calculate the energy contained within the steam (enthalpy). Since we also are measuring the actual steam flow, we can now directly control the energy entering the heater due to the steam. This is a full model of the process. We measure and calculate the energy demand required by the water and directly control the heating energy provided by the steam.

The control configuration is rescaled such the inner loop controls the total BTU/Hr provided by the steam while the feed forward and outer loop is rescaled to BTU/Hr.

The result of this set of blogs on the heater project is a take-away with several lessons.

- Many of the control projects begin as an afterthought.

- Budgeting, scope and schedule need proper attention.

- Major needs are not included in base design.

- Operational efficiencies may not be appreciated.

- Skill set of the Process Engineer may not include adequate control skills.

- The Process Engineer may understand process very well but not all of the associated interactions needed for the application and design of the needed control arrangement.

- Management and operations live with the limitations of the control process. They do not want to spend the money or shut down production for any enhancements. The revenue they may lose due to the maintenance shutdown is a deterrent to any appropriate upgrades to the system.

- Most control projects do not evolve beyond first simple regulatory control implementation (Process Measurement -> PID controller -> Manipulated device).

- Extensive efforts are made to adapt and modify the tuning parameters with respect to the existing measured parameters but no additional efforts are made to add instrumentation and properly enhance the model of the application.

- Spending the time and effort at the beginning of the project to determine scope of instrumentation and control required for the long-term best profit over the life of the system will pay off large in the long run. Establishing a proper design and cash-flow will identify the extent of modeling that will be cost effective.

Next time – How do we best determine and design the complexity of the needed control modeling: Grinding, drying and transport project – Phase 1