Industry Experience

Liquefication

When super-cooled to -260°F, natural gas transforms from a gaseous state into a liquid, allowing it to take up 600 times less space. Excel has experience in the liquefication of natural gas, helping make it much more feasible and economical to transport over long distances.

Propane Air Mixing

Propane-air (also known as LPG-air or SNG) is synthetic natural gas formed by mixing vaporized propane with air. Once mixed, it forms a homogenous mixture that can be used as a direct replacement for natural gas in combustion applications.

Distillation

Distillation is used to separate mixtures of liquids by exploiting differences in the boiling points of the different components. Excel has experience in facilities that leverage distillation in the manufacture and purification of oil and gas.

Tank Farms

Refinery tank farms are the largest units in terms of numbers of plant items in any refinery. We have worked with clients to automate tank farm systems to help streamline operations, supply and demand planning, sales orders, and inventory.

Industry Experience

Services

Industrial Process Automation

Our team’s strong mix of process and automation know-how enables us to take projects from concept and functional requirement through implementation and commissioning, paired with our extensive experience in a wide variety of PLC/HMI and DCS platforms.

IT/OT System Engineering

With the integration of manufacturing systems and processes with back-end hardware and software for conveying and processing information, operational technology (OT) and information technology (IT) are converging and becoming increasingly the same. To execute a successful project in today's world, your OT team needs to be able to communicate effectively with your IT team – and we can help.

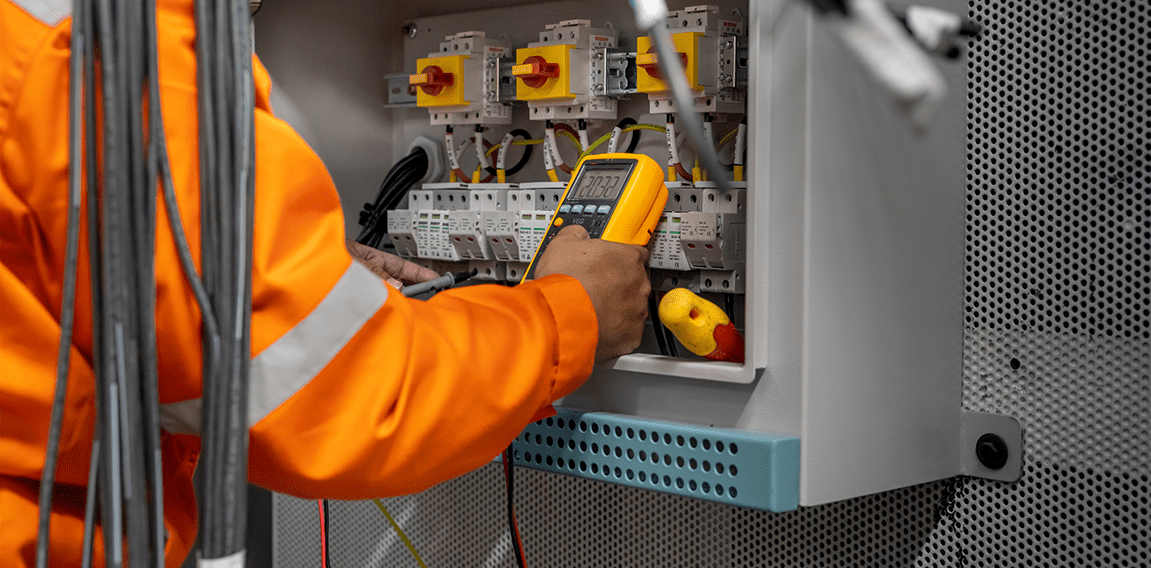

Electrical Engineering

Your industry facility and devices need safe, reliable, and smart power to enable production. Having a well-engineered design package for your industrial project can reduce costs and accelerate installation. From the incoming utility power to the plant floor, we can work with your team and the construction team to ensure the electrons go where they need to go.

Power System Studies

Our team of engineers can perform a comprehensive arc flash analysis and provide facility owners with the information necessary for employees to work safely on electrical equipment while remaining OSHA- and NFPA70E-compliant. Based on the results of the arc flash study, we provide custom arc flash labels for your equipment, updated electrical drawings, and a full report including analysis and recommendations to reduce and/or properly address arc flash hazards.

Project & Construction Management

Challenging projects require superior organization and facilitation of scope, schedule, and budget. Using best practices and standards suited to your project, our team of experienced professionals can help you manage your project during all phases, from planning and scoping to design and construction.

NRTL Evaluations

All electrical equipment in your facilities must be approved, identified, listed, or labeled by an OSHA-accredited nationally recognized testing laboratory (NRTL) – or you could be at risk of costly fines and delays. Excel provides expert-led NRTL field evaluations to ensure your sites are compliant today and safe and productive in the long term.

Infrared Thermography

To guarantee a reliable electrical system in your facility, you need to make sure you are performing preventive maintenance IR scans of your equipment. IR scans allow you to detect thermal abnormalities of equipment, but they also allow you to do so in a non-intrusive, hands-off way while still getting results in real-time. We can perform baseline scans and then annual scans to identify trends in your assets and equipment.

Why Excel Engineering?

Excel is an experienced, dedicated partner that brings a detail-oriented and relationship-driven approach to every project to ensure it exceeds your goals. Here are just a few of the reasons to partner with us to elevate your oil and gas facility.

-

1

Improved Quality

-

2

Improved Safety

-

3

Increased Productivity

-

4

Reduced Costs

-

5

Maximized Throughput

-

6

Improved Asset Reliability

-

7

Improved Product Life-Cycle Management

-

8

Improved Manufacturing Intelligence

News & Insights

Keep up with Excel's latest and dig into industry insights from our team of masterful minds.